Eco-Friendly Professional Spray and Chemical Application Cabinets

Home » Garment Dry Process » Chemical Spray Cabinet » Eco-Friendly Professional Spray and Chemical Application Cabinets

Eco-Friendly Professional Spray and Chemical Application Cabinets

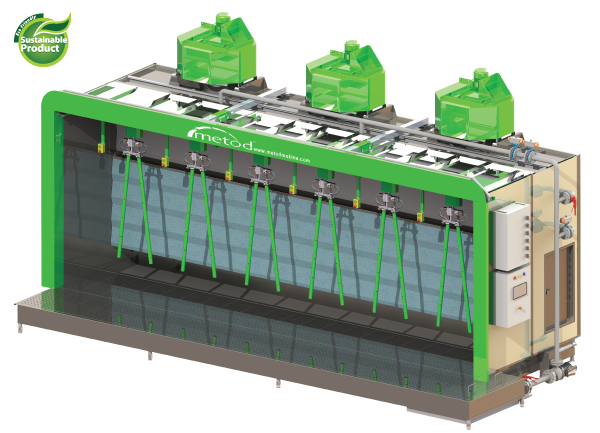

Chemical application cabinets use 304 and 316 Cr-Ni stainless steel panels. Main pool is 2.5 mm 316 Cr-Ni stainless steel. The top pool, water curtain, filter tank, and side panels are 1 mm 304 Cr-ni Stainless steel. This mechanism flushes air via nozzles. Flush nozzles bind chemical or permanganate particles unavoidable by water screen. Detachable nozzles can be cleaned.

Two valves control the top carriage container and nozzle pressure. Water is filtered twice by the pump from the bottom tank to the cabinet top. Water impurities are prevented by this twofold filtering system. An emptying valve releases system water.

The water screen and air flushing system bind chemical particles. Two fan absorption devices are at the water screens’ bottom and center. This method effectively absorbs chemical odors and prevents their spread.

The cabinet houses the heat and contactor-protected electrical board. Light comes from fluorescent armatures. The number of robots determines cabinet length.